The performance of solar panels in high-temperature environments is a critical consideration for maximizing energy generation and system efficiency. Recent advancements in solar technology have led to the development of various panel designs, notably 1/3 cut and half-cut solar panels. This article explores why 1/3 cut solar panels are more suitable for high-temperature conditions than their half-cut counterparts

Solar photovoltaic (PV) modules convert sunlight into electricity through the photoelectric effect. The efficiency of these modules is significantly influenced by their operating temperature, which is affected by the current flowing through them. Higher currents lead to increased resistance losses, resulting in greater heat generation and reduced power output. Understanding the current and voltage characteristics of different solar panel designs is essential for evaluating their performance in warm climates.

Table of Contents

Understanding Current and Voltage Characteristics

The performance of solar panels is heavily influenced by their current and voltage characteristics.

1/3 Cut Solar Panels

1/3 cut solar panels are designed to have lower current and higher voltage characteristics. For example, a 1/3 cut panel like the Twisun Pro (TOPCon) has a power output of 430W, with a current of 9.96A and a voltage of 43.2V. This configuration allows for reduced resistance losses, making them more efficient in high-temperature settings.

Half-Cut Solar Panels

In contrast, half-cut solar panels exhibit higher current and lower voltage. A typical half-cut panel with the same power output of 430W has a current of 13.49A and a voltage of 31.88V. The increased current results in higher resistance losses, which can significantly impact performance in elevated temperatures.

The difference in current levels is significant because higher currents lead to increased resistance losses, which are detrimental in hot climates.

Also read: What is Energy Band Gap of Solar Cells?

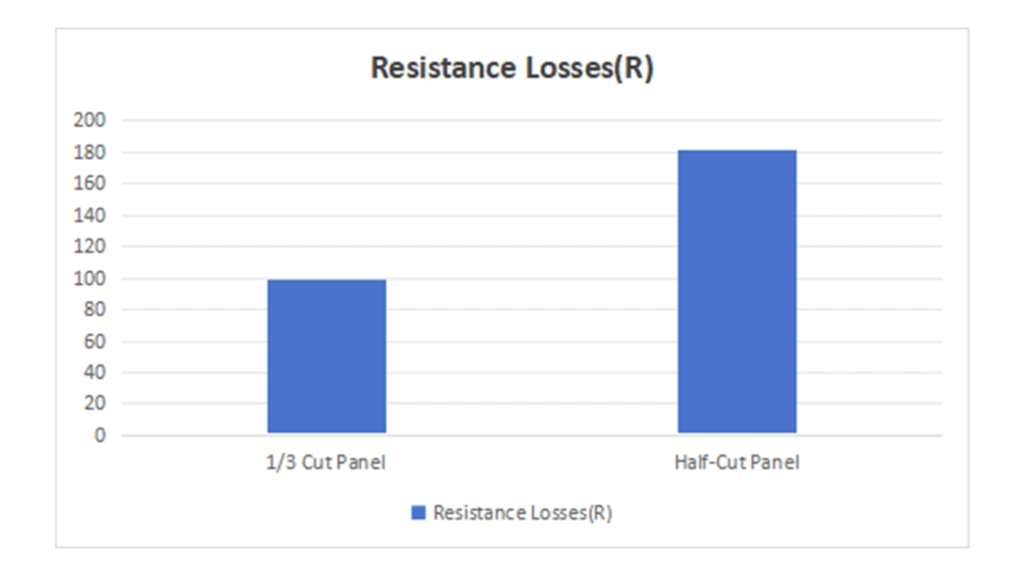

Resistance Losses

Resistance losses in solar panels can be calculated using the formula Pres=I2×RPres=I2×R. Given that resistance remains constant, the higher current in half-cut panels results in greater power losses:

- 1/3 Cut Panel:

- Current I=9.96AI=9.96A

- Resistance Loss Pres=9.962×R=99.2RPres=9.962×R=99.2R

- Half-Cut Panel:

- Current I=13.49AI=13.49A

- Resistance Loss Pres=13.492×R=181.98RPres=13.492×R=181.98R

This indicates that half-cut panels experience approximately 1.83 times more resistance loss than 1/3 cut panels.

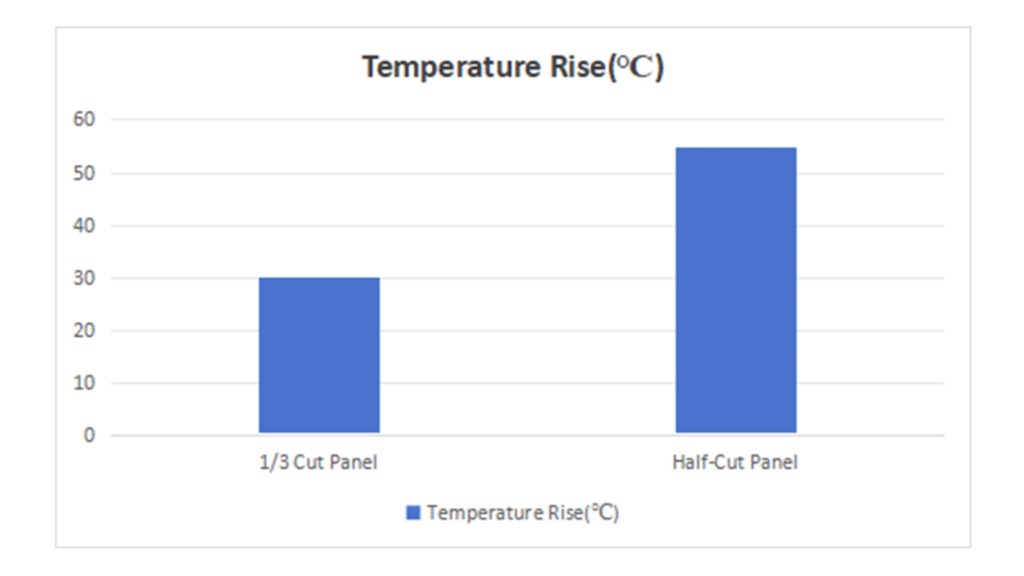

Temperature Rise

The temperature rise in solar panels is directly proportional to resistance losses. Assuming an ambient temperature of 30°C:

Assuming an ambient temperature of 30°C, the operating temperatures would be:

- 1/3 Cut Panel: Operating temperature = 30°C + 30°C = 60°C.

- Half-Cut Panel: Operating temperature = 30°C + 54.9°C = 84.9°C.

This substantial difference in temperature rise (24.9°C higher for half-cut panels) contributes to greater thermal stress and potential efficiency losses.

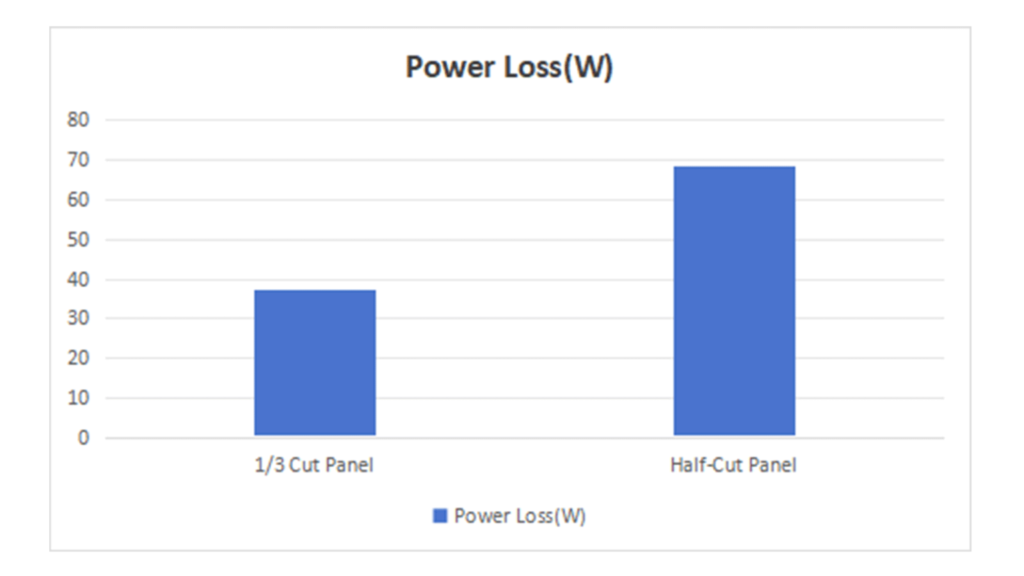

Power Loss

The power loss due to temperature can be quantified using the power temperature coefficient. For example, with a coefficient of -0.29%/°C:

- 1/3 Cut Panel:

- Power loss = 430W × (-0.29%/°C × 30°C) = -37.41W

- Half-Cut Panel:

- Power loss = 430W × (-0.29%/°C × 54.9°C) = -68.46W

This results in half-cut panels losing about 31.046W more power than 1/3 cut panels, equating to an additional 7.22% power loss.In practical terms, for a 10kW system operating under average sunlight conditions, this translates into an annual generation loss of approximately 45.33 kWh, which could significantly impact energy production for a typical household.

Book 1/3 Cut Solar Panels

Also read: Discover the Best Solar Panels for Soil-less Farming Today!

Annual Power Generation Loss

When considering a 10kW TOPCon photovoltaic system with an average sunlight duration of 4 hours/day, the annual power generation loss for half-cut panels compared to 1/3 cut panels is significant:

- Annual Power Generation Loss: Approximately 45.33 kWh, which is comparable to the energy consumed by a microwave oven used daily for an entire year.

Conclusion

In summary, 1/3 cut solar panels exhibit clear advantages over half-cut panels in high-temperature environments due to their lower current, reduced resistance losses, and minimized temperature rise. These factors contribute to enhanced power generation efficiency and stability, making 1/3 cut panels a superior choice for photovoltaic systems operating in challenging thermal conditions.

The Twisun Pro model exemplifies this technology, showcasing exceptional performance and reliability in high-temperature settings while mitigating risks associated with excessive heat. Choosing 1/3 cut solar panels can lead to improved efficiency and long-term safety for solar energy systems.